Product

Event

Follows

Product Sale

How We Work

We adhere to a meticulous production process that surpasses industry standards, ensuring the utmost quality in every product we create. Our technologically advanced approach considers even the finest details, granting our products a distinct competitive edge.

Pre-Production quality check

All raw materials, parts, and machinery are subjected to rigorous quality inspections prior to commencing production. Production tracking and quality control are essential throughout the entire production procedure.

During Production

Guarken's professional quality inspectors will strictly control every step of the production process, covering semi-finished product winding, soldering, racking, polishing, grinding, plating, as well as final racking and final packaging, to ensure that it is executed in full compliance with the production drawings and customers' requirements.

Post-Production quality check

In accordance with the requirements of ISO 12870 standard, the finished products will undergo a stringent quality inspection process in our independent laboratory testing center, through a series of sophisticated testing methods and professional evaluation, in order to ensure that each pair of glasses exported can meet the qualification standards, and become a product of excellent quality.

Innovation

Always standing at the forefront of technological innovation, we continue to explore and integrate the latest technology and are committed to enhancing the comfort, functionality and personalization of our products. Through intelligent design, high-precision manufacturing process and the use of environmentally friendly materials.

We continue to innovate in the field of materials, adopting environmentally friendly, high-performance new materials to reduce weight, enhance comfort and durability, while meeting the needs of fashion and functionality, leading the industry trend.

100% Guarantee: Complete inspection of each shipment

We maintain a tight quality control. Checks are done at every step of production. The final product goes through a rigorous check before shipping. We have a professional QC team, who have rich industry experience and professional knowledge, and are able to master various testing methods and techniques. These quality control personnel are not only responsible for the daily testing of products, but also involved in product quality improvement and enhancement work, to protect the quality of the enterprise's products.

Well-equipped Production Line

Our production lines are well-equipped and standardized, which can meet different customers' requirements.

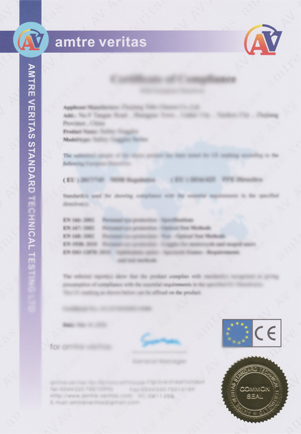

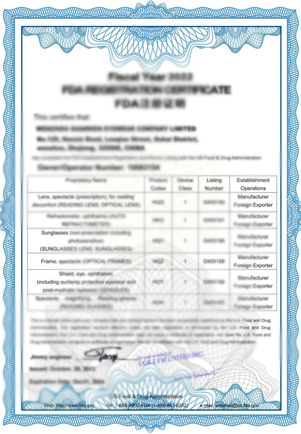

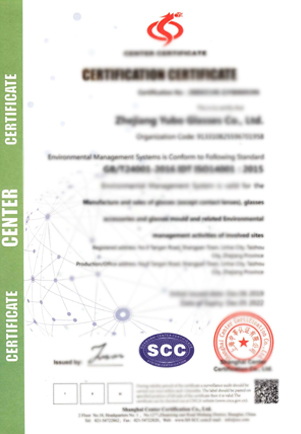

Customer DemandFactory Certification